Following on from our recent piece ‘Who knows what a fuel cell is?’ we now dive deeper into the great variety of applications that hydrogen can power with zero-carbon emissions.

Today we’re putting Airbus’s hydrogen technology in the spotlight.

Airbus is the largest manufacturer of airliners worldwide, designing, producing, and selling commercial aircraft. It operates through distinct divisions, namely Defence and Space, and Helicopters.

But it is Airbus’s goal to create the world’s inaugural hydrogen-powered commercial aircraft by 2035 that interests us most. In pursuit of this objective, the company has officially initiated a multi-year demonstrator program. The program aims to extensively test various hydrogen technologies, both on the ground and in-flight, to evaluate their feasibility and effectiveness.

It was back in 2015 that the development of one of the most formidable engines ever designed for an Airbus aircraft was nearing completion. However, prior to its installation on the designated A350-1000 aircraft, rigorous flight and ground testing was essential. This customary procedure is employed to assess the performance and reliability of new technologies before they are implemented for operational use.

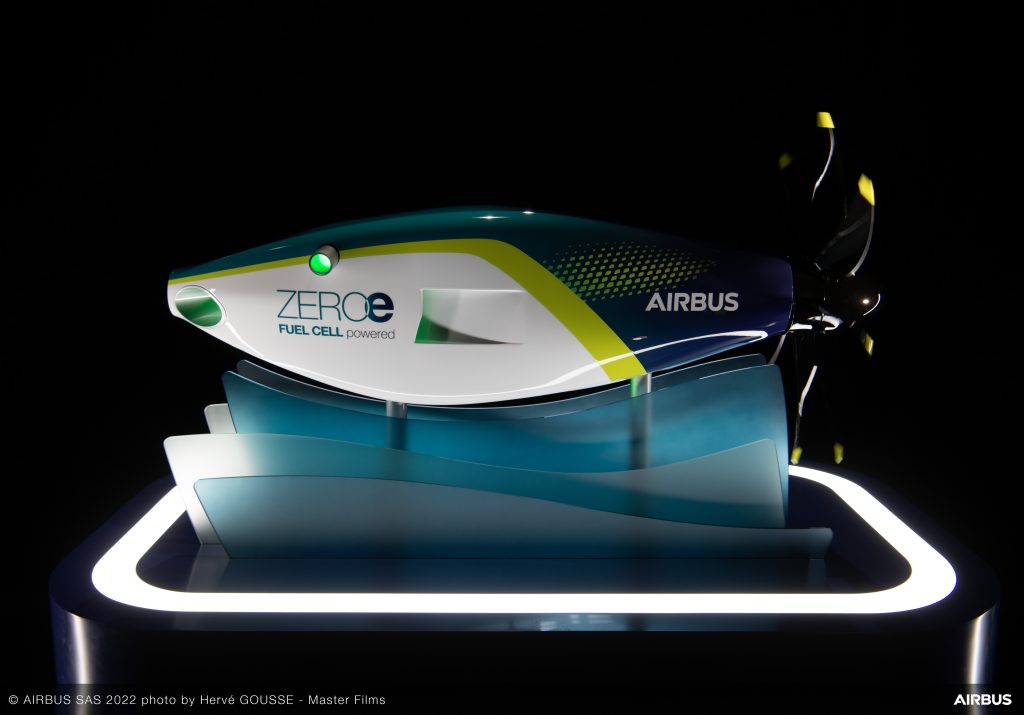

Airbus have set themselves the goal of fully operational hydrogen-powered flight by 2035. (Pictured the Airbus ZEROe hydrogen aircraft)

Hence, on a delightful autumn day, the aircraft equipped with the developmental engine embarked on its journey from Airbus’ facilities located in Toulouse. The test flight, which spanned 4 hours and 14 minutes, meticulously assessed the engine’s performance across various power settings while ascending to altitudes of up to 35,000 feet.

However, contrary to expectations, the A350-1000 was not utilised for the test flight. Instead, it was the A380 MSN1, the very first A380 aircraft ever manufactured, that took to the skies.

Renowned as the largest and most spacious passenger jet ever constructed, the A380’s substantial size renders it an ideal platform for conducting tests and experiments.

Presently, the A380 MSN1 test aircraft has been assigned a new purpose: spearheading the testing of crucial technologies required to bring the world’s inaugural hydrogen-powered commercial aircraft to the market by 2035. This aircraft will play a pivotal role in validating and advancing the necessary innovations for this ground-breaking aviation milestone.

“The A380 MSN1 is an excellent flight laboratory platform for new hydrogen technologies,” says Mathias Andriamisaina, Airbus ZEROe Demonstrator Leader. “It’s a safe and reliable platform that is highly versatile to test a wide range of low-carbon technologies. In addition, the platform can comfortably accommodate the large flight test instrumentation that will be needed to analyse the performance of the hydrogen in the hydrogen-propulsion system.”

The A380 MSN1 test aircraft has been assigned a new purpose: spearheading the testing of crucial technologies required to bring the world’s inaugural hydrogen-powered commercial aircraft to the market by 2035.

The existence of a demonstrator aircraft is of course essential in the advancement of aviation technology. Its primary purpose is to thoroughly evaluate and validate the feasibility of various designs, processes, fuels, materials, and equipment, both during ground testing and actual flight operations. The insights gained from these tests are crucial for refining and certifying the final product. Demonstrator aircraft also play a significant role in showcasing innovation to a broader audience, including government officials, investors, journalists, and the general public, highlighting the remarkable progress achieved in the field.

Airbus has established a strong history of initiating demonstrator programs aimed at testing cutting-edge technologies. The E-Fan family, for instance, showcased the possibilities of all-electric flight, while the Vahana and CityAirbus demonstrators played a crucial role in advancing Airbus’ vision for urban air mobility. In the most recent development, the E-Fan X program was instrumental in exploring the potential of hybrid-electric propulsion. These demonstrator programs have been instrumental in pushing the boundaries of innovation within Airbus and shaping the future of aviation.

The upcoming ZEROe demonstrator will take on the crucial role of testing revolutionary low-carbon aviation technologies. This remarkable aircraft will feature four liquid hydrogen tanks positioned at the tail, along with a hydrogen combustion engine mounted on the rear fuselage. The liquid hydrogen distribution system will supply the conditioning system, where the liquid hydrogen will undergo a transformation into its gaseous state. Subsequently, the gaseous hydrogen will be introduced into the engine, where it will undergo combustion to generate propulsion power. This innovative setup will pave the way for exploring the possibilities of sustainable aviation in the future.

The upcoming ZEROe demonstrator will take on the crucial role of testing revolutionary low-carbon aviation technologies. This remarkable aircraft will feature four liquid hydrogen tanks positioned at the tail, along with a hydrogen combustion engine mounted on the rear fuselage.

“This isn’t Airbus’ first experience with hydrogen-powered flight,” Mathias explains. “From 2000 to 2002, Airbus was a key partner in the European Union’s Cryoplane research project. Building on these academic inquiries, we’re proud to take the testing of hydrogen combustion to the next level.”

The hydrogen combustion engine plays a vital role in the ZEROe demonstrator program, highlighting its significance in advancing sustainable aviation. Engine manufacturers have long collaborated closely with Airbus on various demonstrator programs over the years, fostering a strong partnership. With the ZEROe demonstrator, this collaboration continues, emphasising the shared commitment to pushing the boundaries of innovation and developing environmentally friendly aviation solutions.

CFM International, a collaboration between GE and Safran, has been entrusted with the development and testing of the hydrogen combustion engine. The company’s focus will be on modifying the combustor, fuel system, and control system of a GE PassportTM turbofan to operate on hydrogen fuel. The selection of this engine was based on its physical dimensions, advanced turbo machinery, and fuel flow capacity. CFM International’s expertise and capabilities make it well-suited for this crucial task in advancing hydrogen-powered aviation technology.

The individual technology components, including the hydrogen tanks, hydrogen combustion engine, and liquid hydrogen distribution system, will undergo comprehensive ground testing. Following that, the complete system will be subjected to ground testing as an integrated unit before progressing to flight testing. The anticipated timeline for the first flight is within the next five years, marking a significant milestone in the development of this ground-breaking aviation technology.

The hydrogen combustion engine plays a vital role in the ZEROe demonstrator program, highlighting its significance in advancing sustainable aviation. Engine manufacturers have long collaborated closely with Airbus on various demonstrator programs over the years, fostering a strong partnership.

Firstly, Airbus’ hydrogen investment drives research and development in hydrogen technologies, fostering innovation and technological advancements, and secondly it yields positive implications that extend throughout the entire hydrogen supply chain, leading to greater urgency for hydrogen production, storage, and transportation methods. Furthermore it creates a demand for hydrogen fuel, spurring the growth of hydrogen production infrastructure.

In turn Airbus’ investment will help drive economies of scale, making hydrogen production more cost-effective. This reduction in costs will accelerate hydrogen becoming a more competitive and viable option for other industries, such as energy and heavy transport.

Firstly, Airbus’ hydrogen investment drives research and development in hydrogen technologies, fostering innovation and technological advancements, and secondly it yields positive implications that extend throughout the entire hydrogen supply chain, leading to greater urgency for hydrogen production, storage, and transportation methods.

There is of course a great deal at stake here. According to the International Civil Aviation Organization (ICAO), aviation is responsible for approximately 2% of global carbon dioxide (CO2) emissions. However, when considering the overall climate impact, including non-CO2 emissions such as nitrogen oxides (NOx), water vapor, and contrail formation, the aviation industry’s contribution seems likely to be closer to 3%. Efforts to reduce aviation emissions are therefore crucial in addressing climate change and achieving sustainability goals.

As a clean and renewable energy source, hydrogen has the potential to significantly reduce greenhouse gas emissions from aircraft. Its combustion produces only water vapor, eliminating harmful carbon emissions. Moreover, hydrogen offers high energy density, making it suitable for long-haul flights.

By embracing hydrogen as a fuel for aviation, we can pave the way for a sustainable and greener future, mitigating the environmental impact of air travel.

Mathias Andriamisaina, Airbus ZEROe Demonstrator Leader says “The A380 MSN1 is an excellent flight laboratory platform for new hydrogen technologies. It’s a safe and reliable platform that is highly versatile to test a wide range of low-carbon technologies”.

To learn more about Ryze Hydrogen, click here.